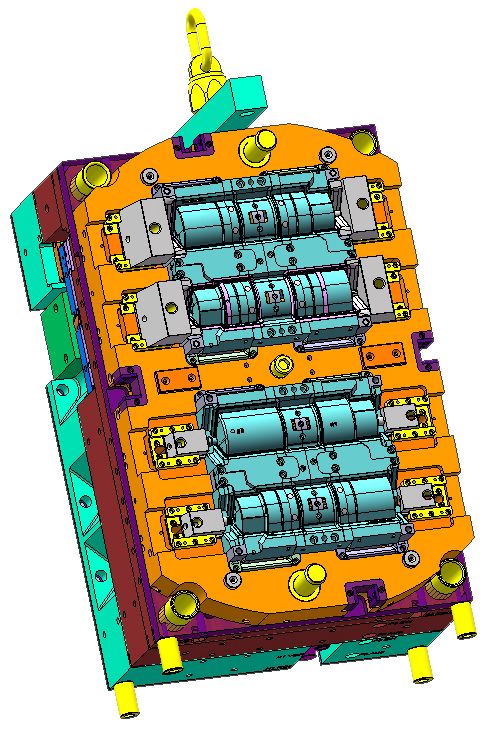

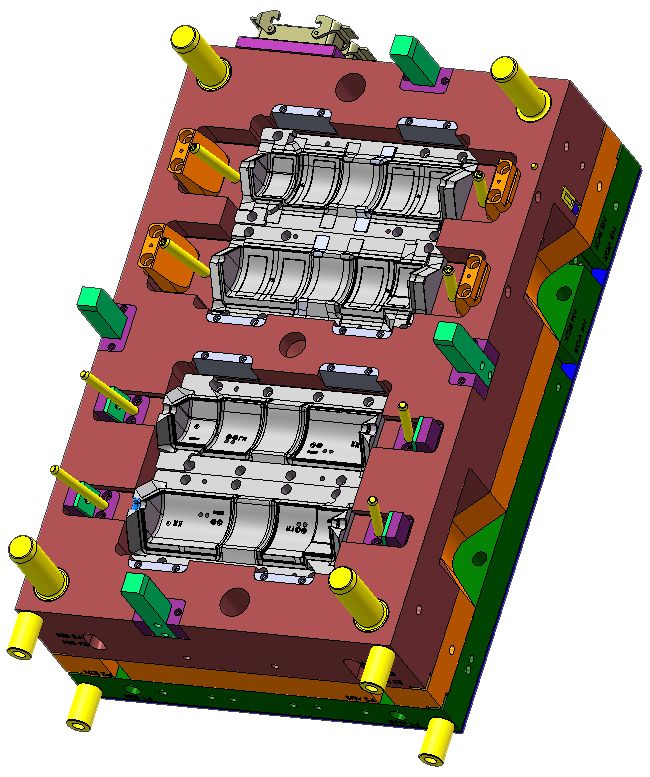

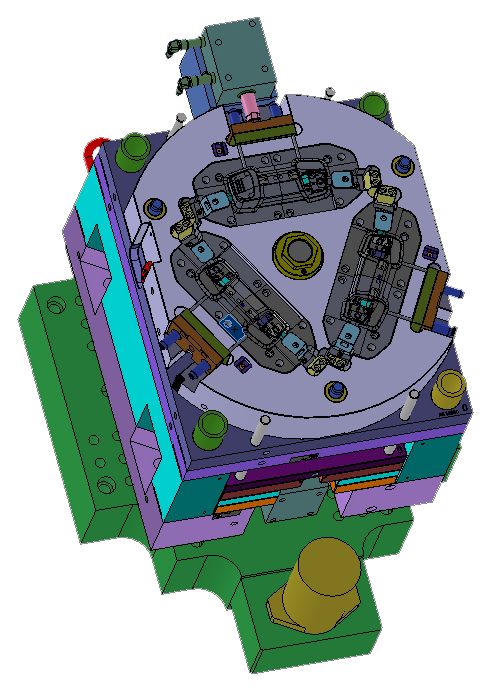

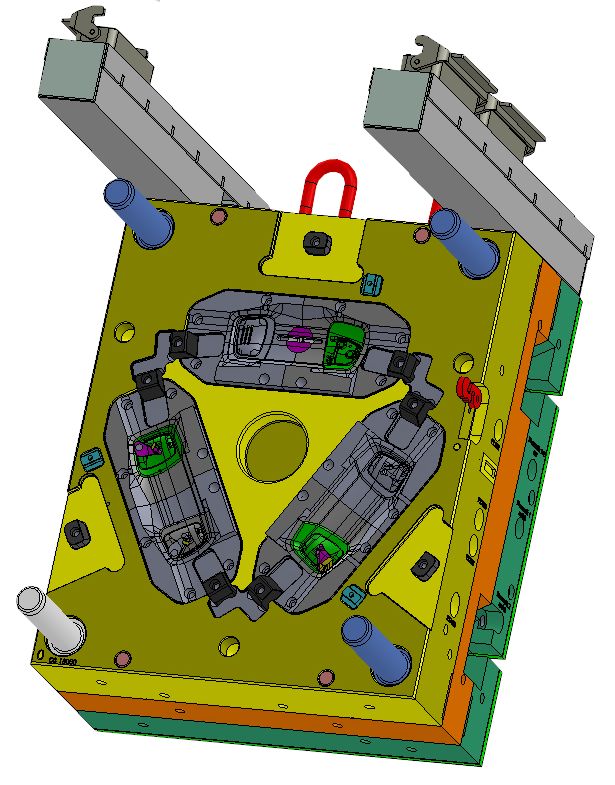

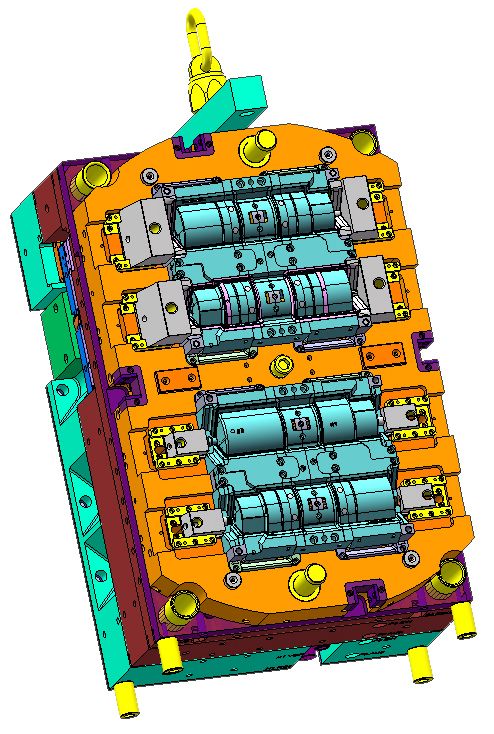

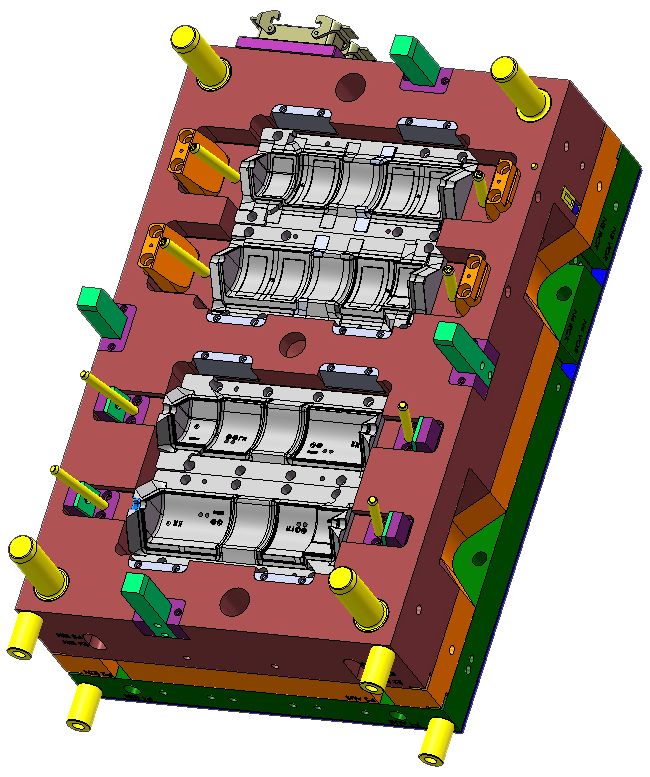

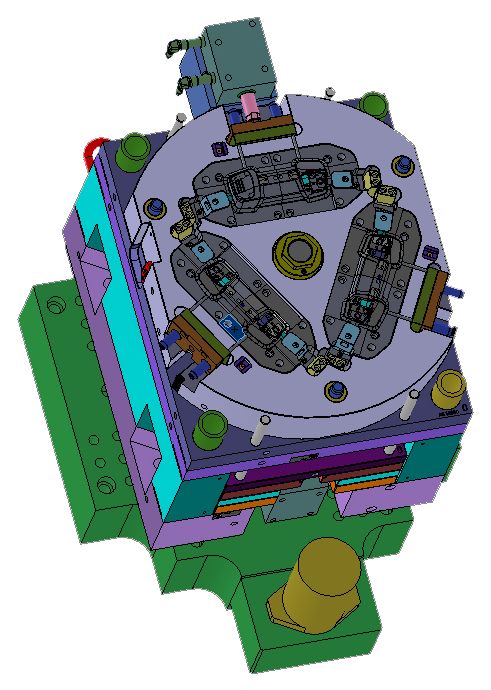

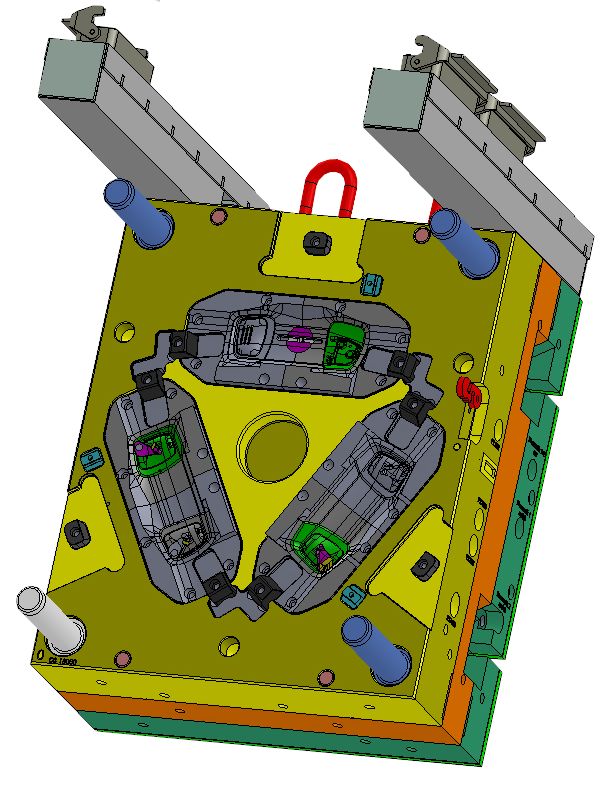

Construction

For more than 40 years, we have been developing and designing intelligent and sophisticated solutions for our customers in the automotive, electronics and consumer goods industries and their suppliers.

We design the injection molds according to function, production and assembly.

We have standardized our development methodology and processes.

OUR EXPERTISE ARE

- Injection molds

- Multi-component molds

- Hot runner molds

- Thermoplastic silicone molds

- Injection moulding

- Stack molds

- Magazine method

- Thread molds

- Insert shapes

- Turntable forms

- Jig

- Warehouse and system technology

OUR PERFORMANCE INCLUDES

- 3D design

- Developments

- Product design

- Design

- Configuration

- Simulations

- Prototype

- Feasibility studies

- Electrode design

Versatile experience, excellent expertise and a high degree of customer orientation guarantee a professional and efficient processing of your orders.

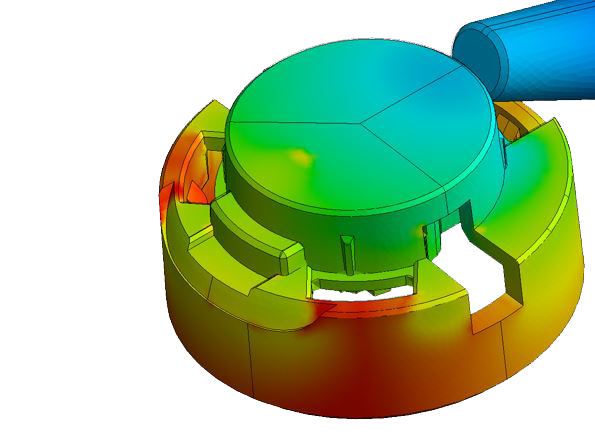

Filling simulations

- Fill simulations with information on pressure, temperature, time and orientation

- Scope of evaluation regarding shear rate, core and fiber orientation

- Thermal tool design with shrinkage and draft

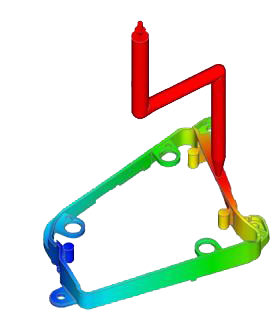

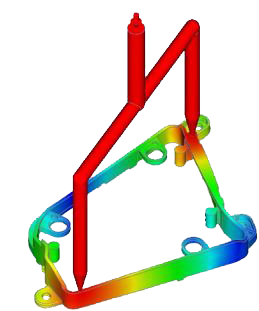

Structural analysis

- Optimize manufacturing and assembly

- Linear and nonlinear deformations

- Tension test according to technical principles and standards.

Your data and manufacturing guidelines are always treated with the utmost discretion. Confidentiality and confidentiality are a matter of course for us.

Contact

Zi-Systeme GmbH

CAD Konstruktionsbüro Ziegler

Silcherstraße 35

D-73061 Ebersbach an der Fils

Tel.: +49 7163 909810

E-Mail: info@zi-systeme.de